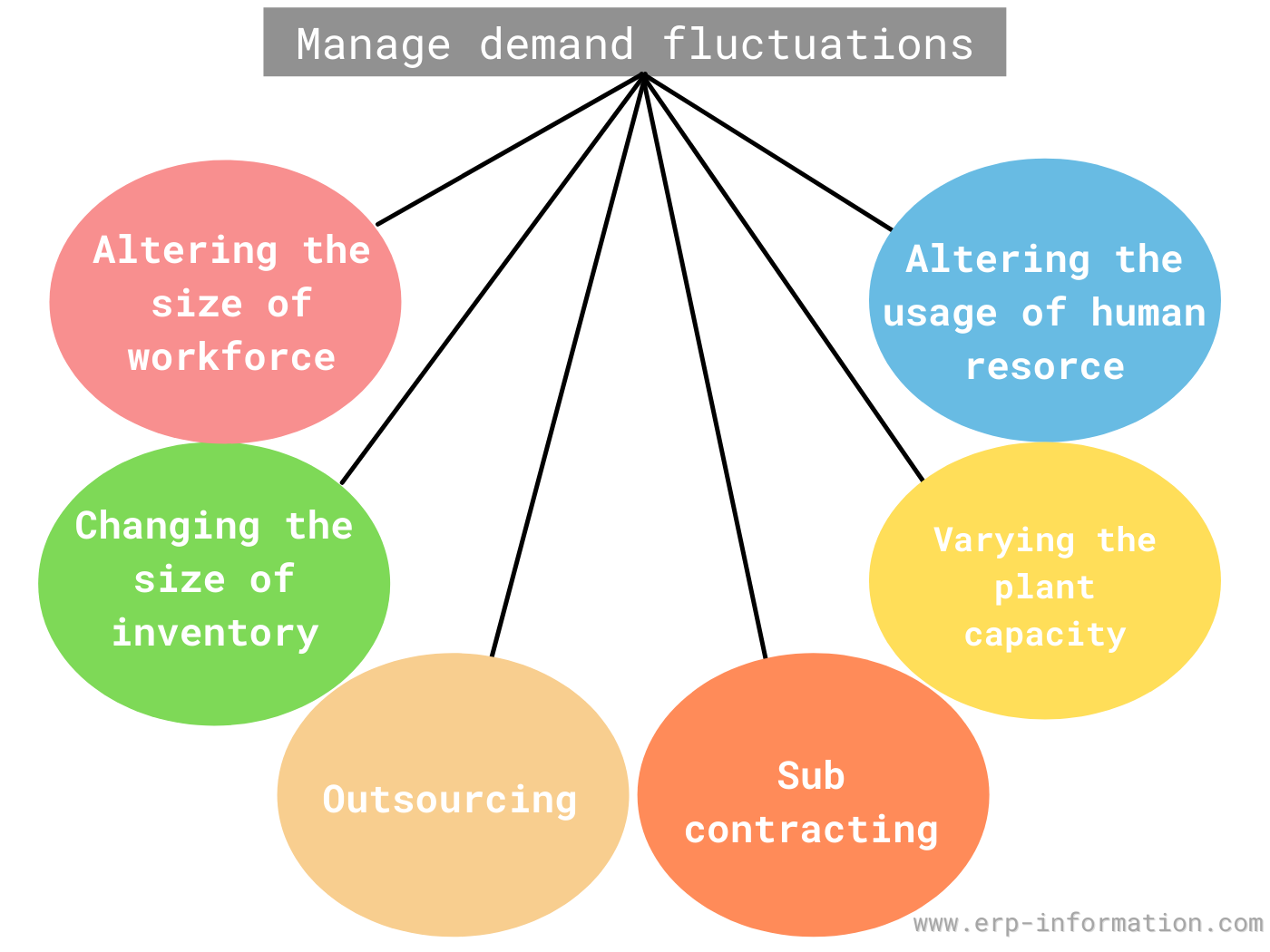

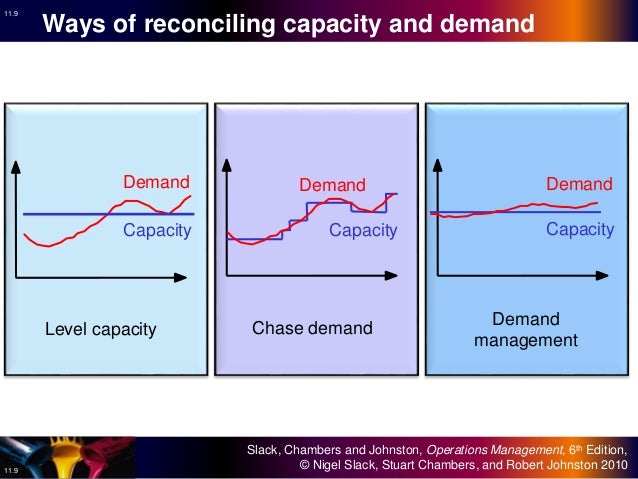

Within the context of the wider UN system, several key documents call for an effective and common approach at the country level in advocating for and taking action on capacity development2 In particular regard to measuring capacity development results, the 07 Triennial Comprehensive Policy Review (TCPR) "requests theThe level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to followPurpose of Capacity Plan Provide the purpose of the capacity plan For example Capacity planning is an important part of infrastructure and deployment planning A capacity plan supports the goal of optimum, and cost effective, provisioning of organizational resources and services by matching them to business demands

Book Production And Operations Management

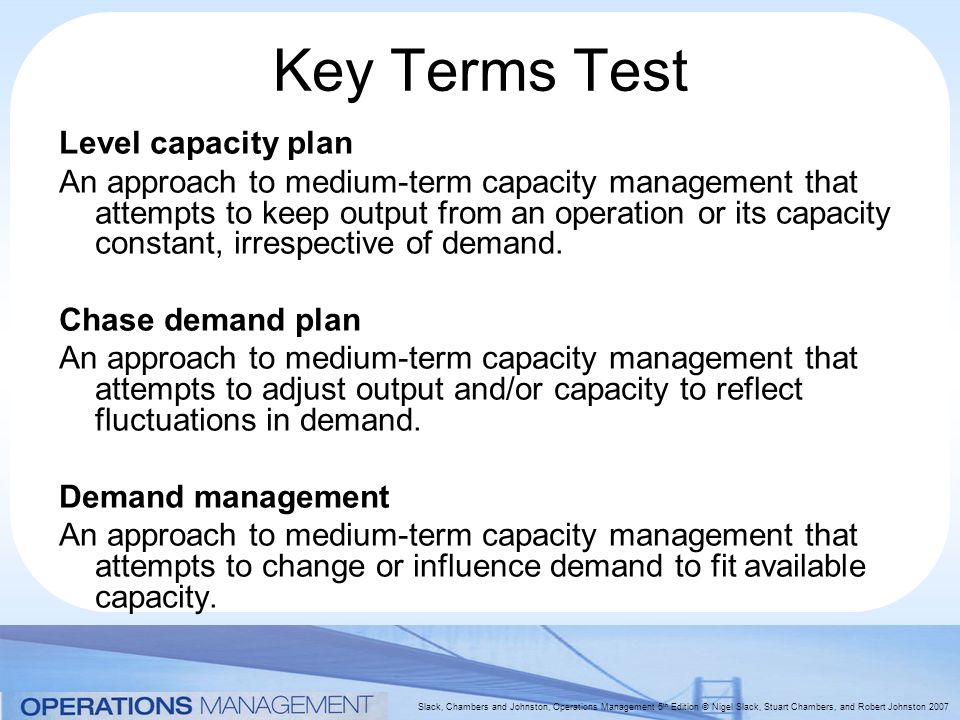

What is level capacity plan

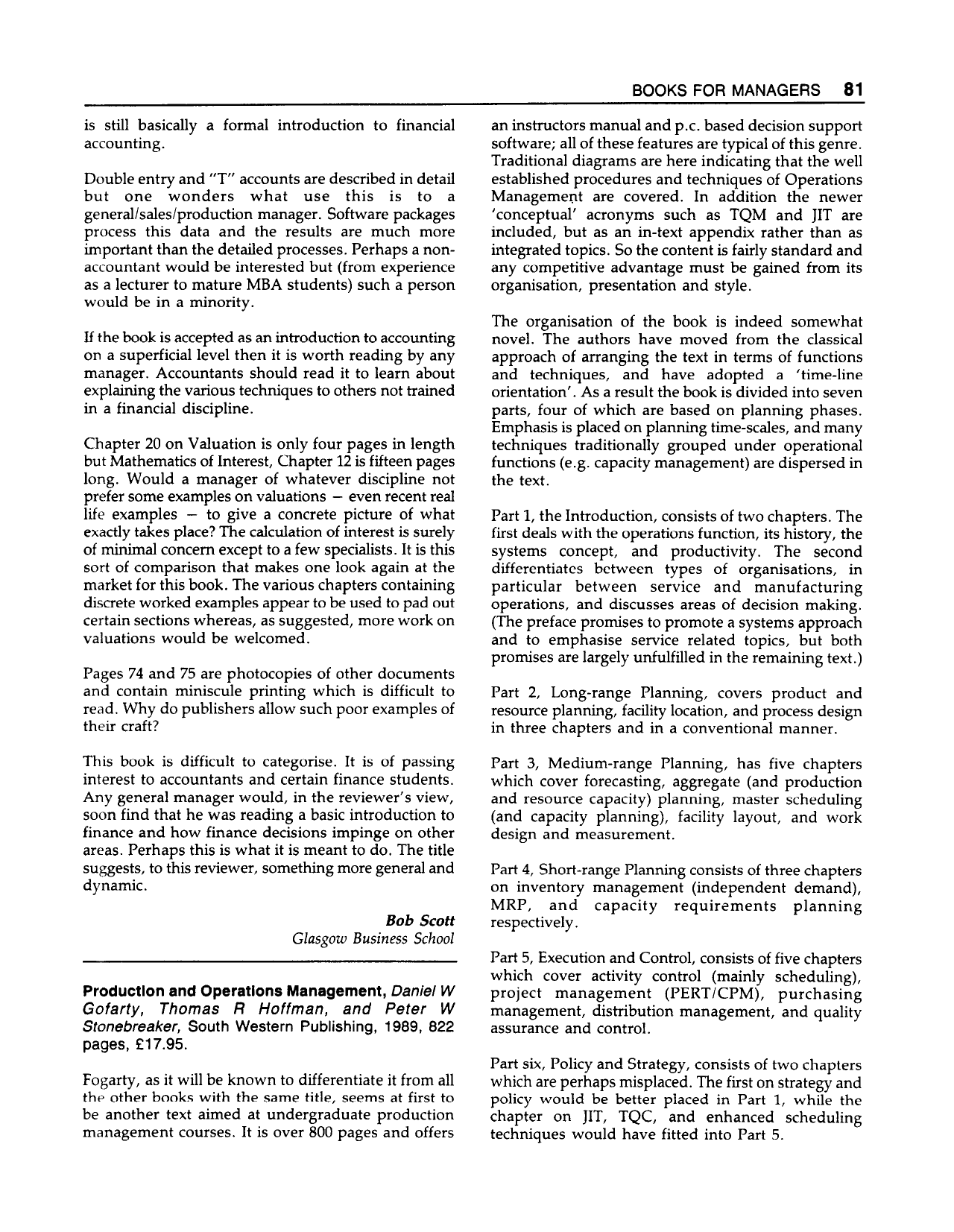

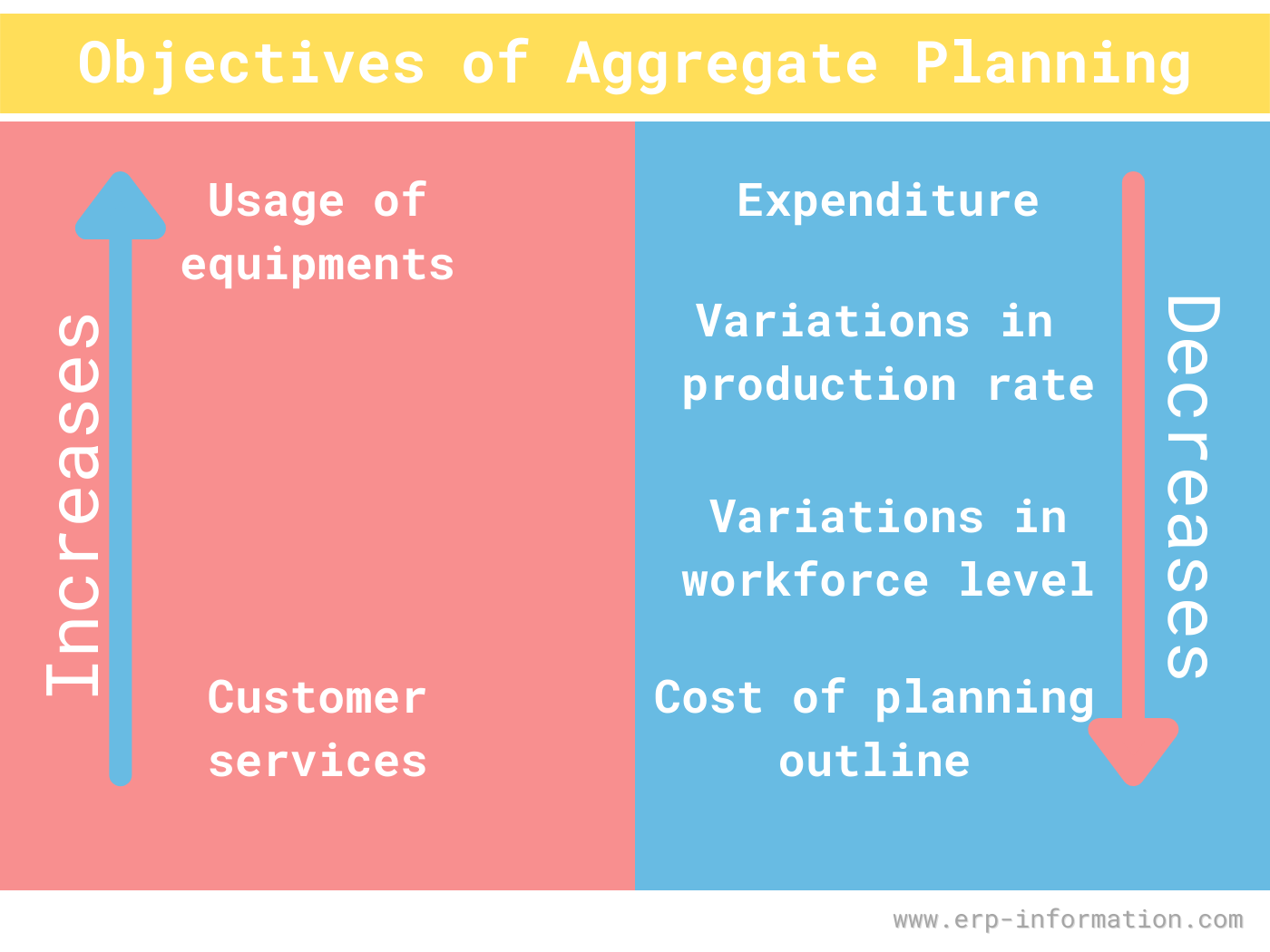

What is level capacity plan-Changes in production level cost $100 per unit due to hiring, line changeover costs, and so forth Assume 0 units of initial inventory Extra capacity may be obtained by subcontracting at an additional cost of $15 per unit over and above the company's producing them itself on regular timeOwnership and sustainability This approach is consistent with the Paris Declaration on Aid Effectiveness, signed by more than 100 bilateral donors and developing countries, which states that the ―capacity to plan, manage , implement and account for results is critical for achieving development objectives‖ ii To achieve these ambitious

Capacity Planning And Control Ppt Video Online Download

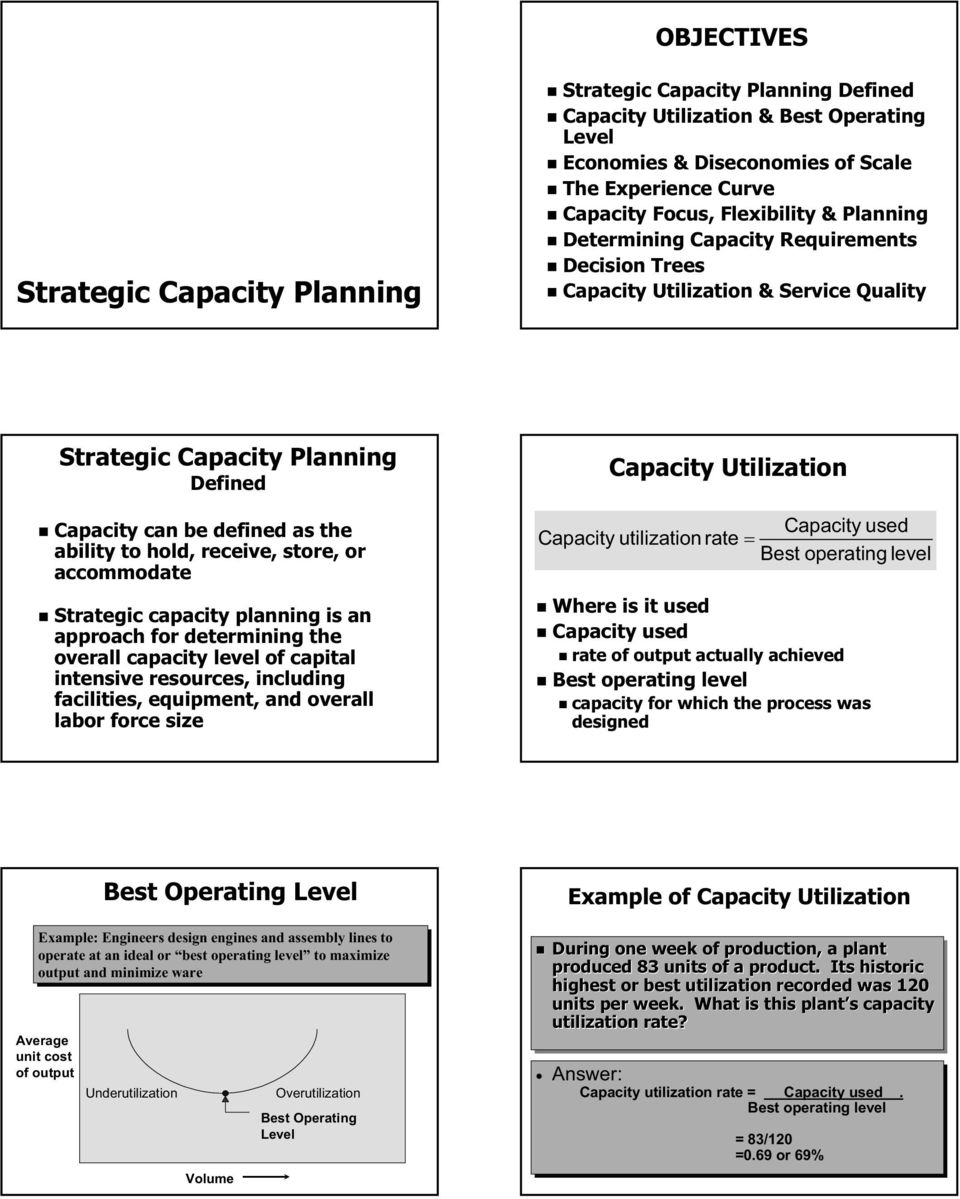

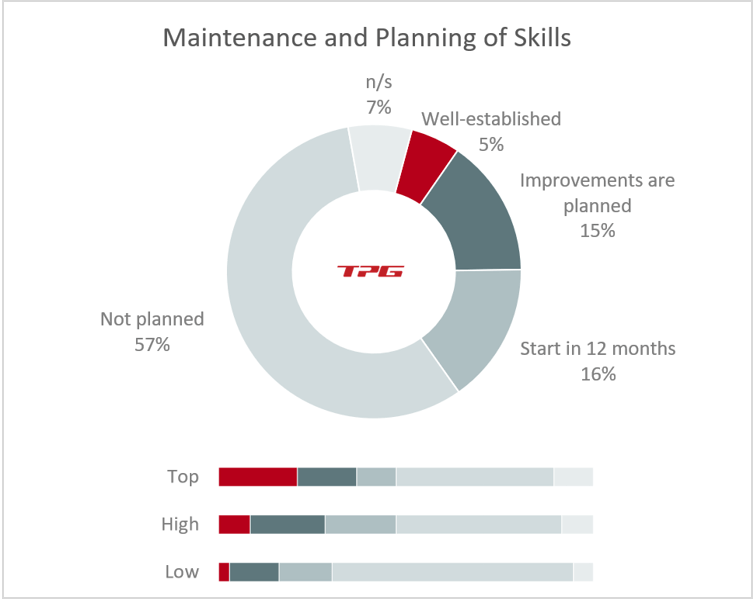

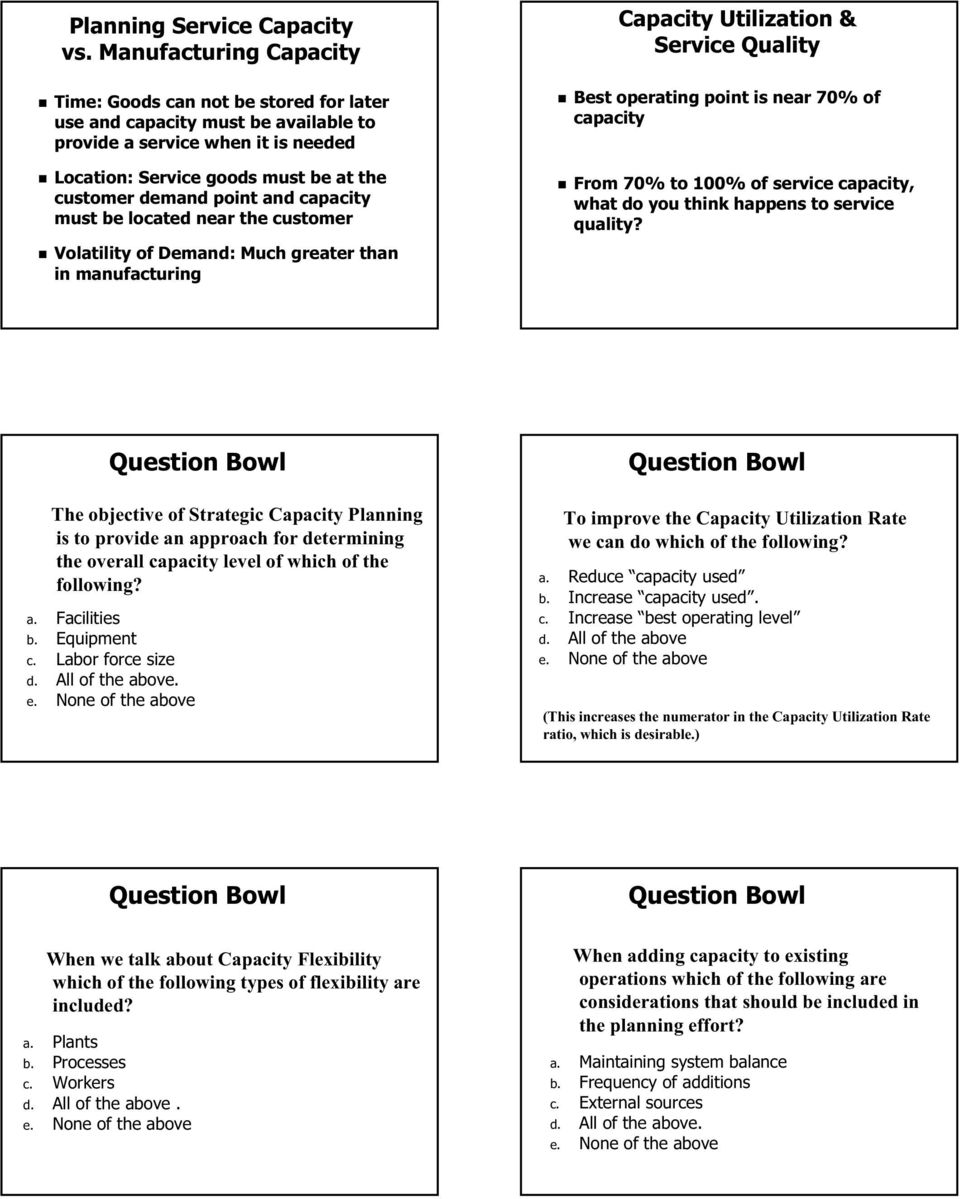

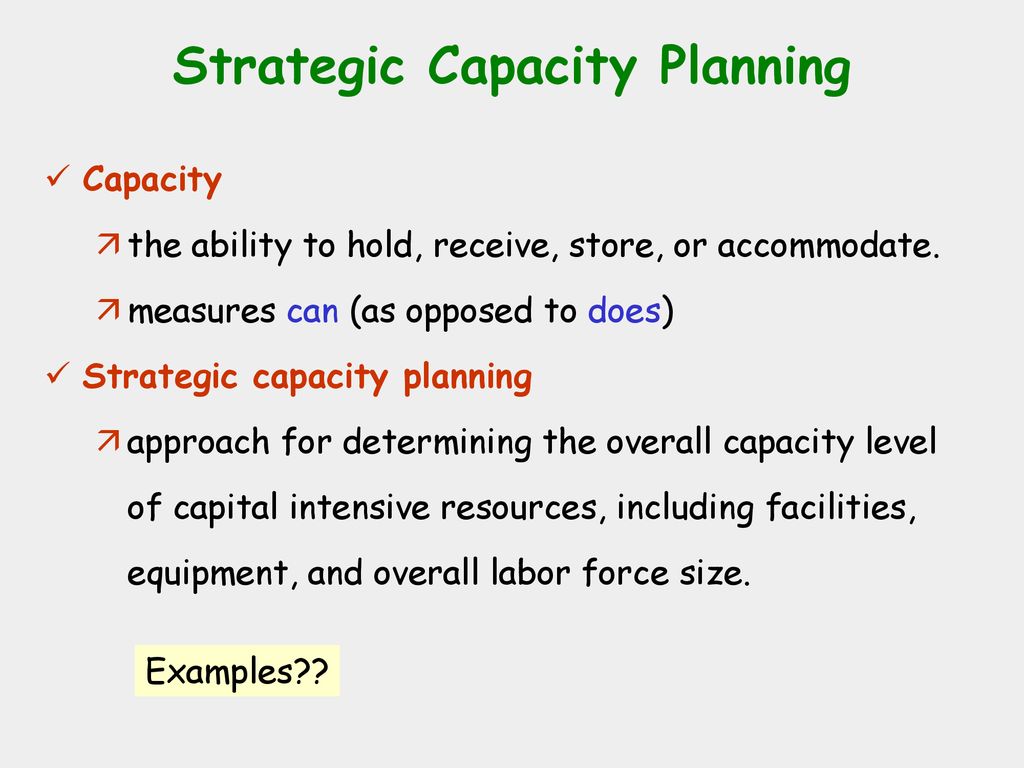

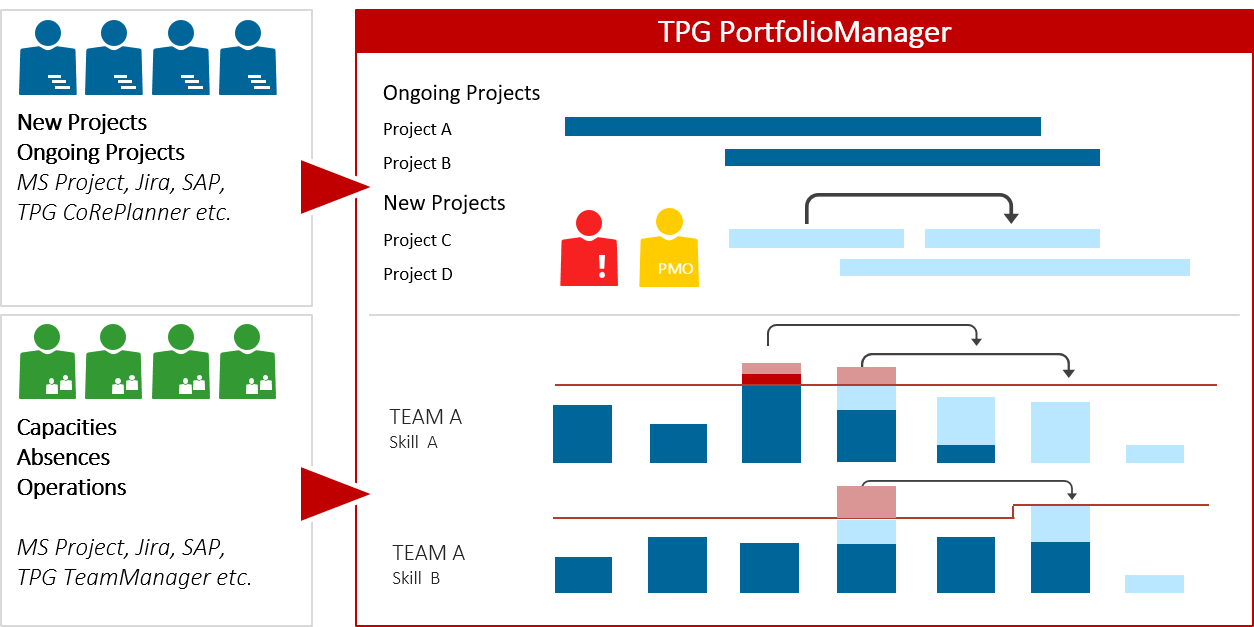

Capacity Planning refers to the arrangement in which organizations or teams match employees together with the needs of a project Capacity is the optimum level of work that can be done within an established period Usually, it is measured in the quantity of work that isSep 06, 17 · 3 Resource planning is near term and resource based Unlike capacity planning where the focus is skills, resource planning shifts the focus to individual resources And whereas capacity planning looks long term, resource planning normally looks no further than the next few months And this is importantB Scheduling is a shortterm capacity planning approach used both in manufacturing and service operations C The purpose of scheduling is to set overall longterm output level in the face of fluctuating or uncertain demand

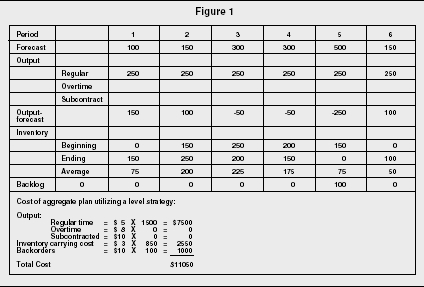

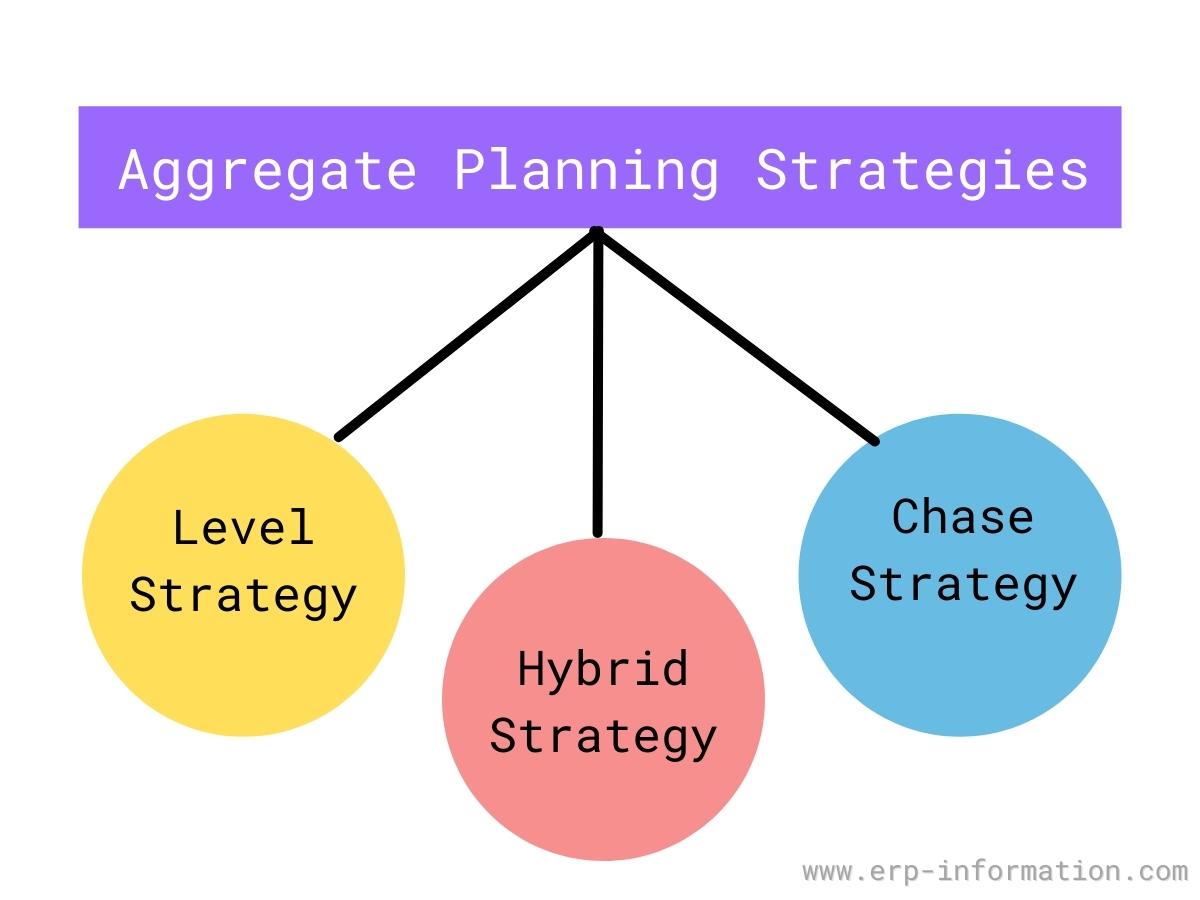

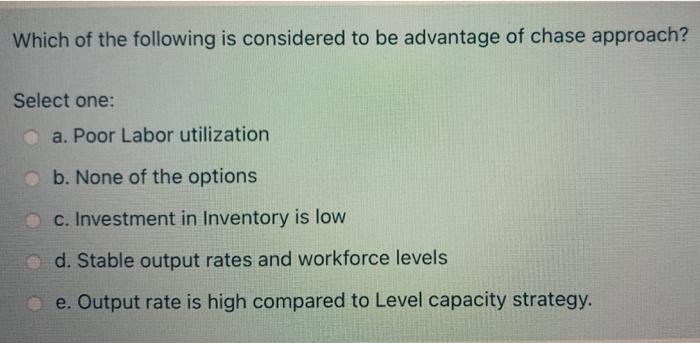

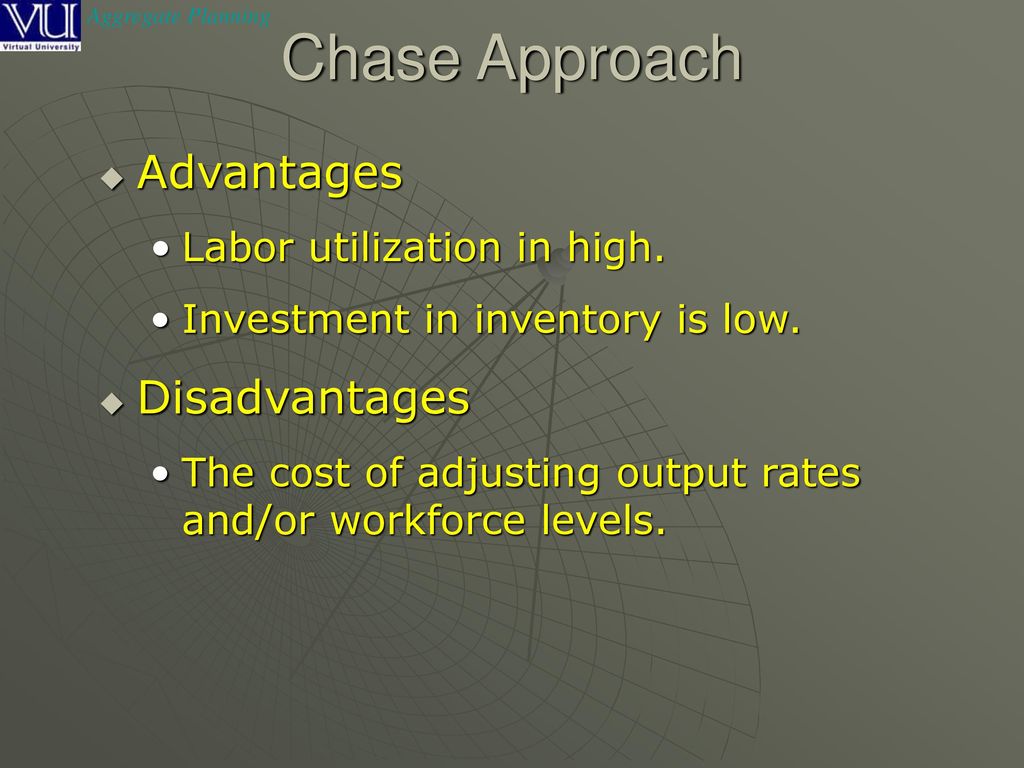

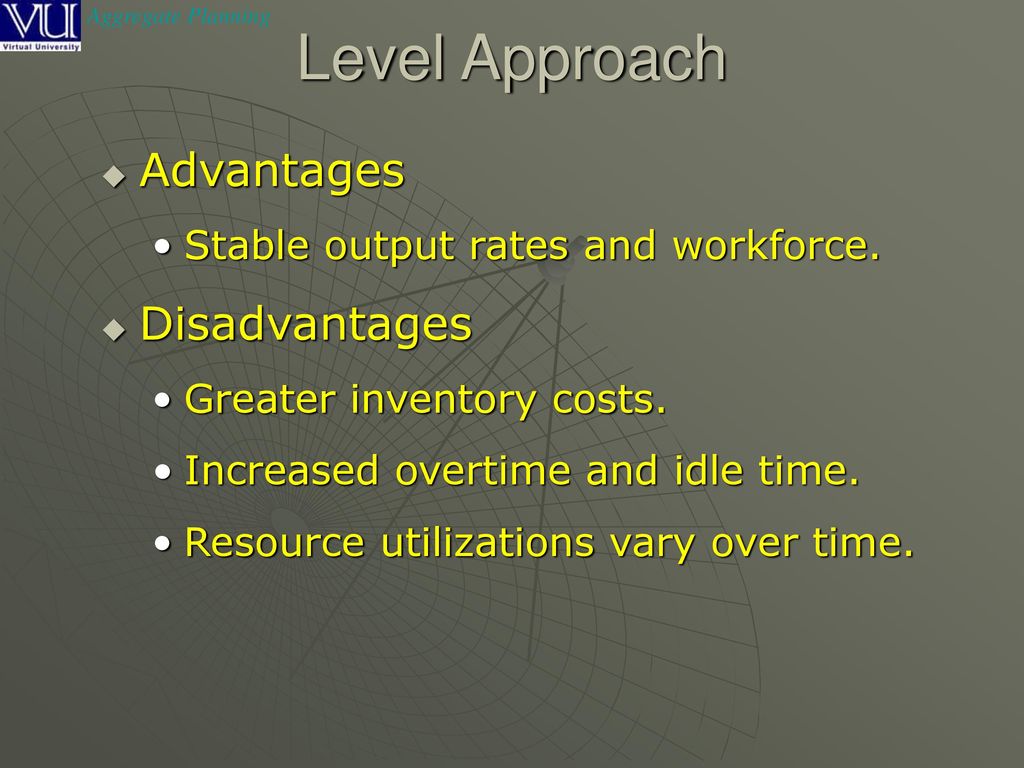

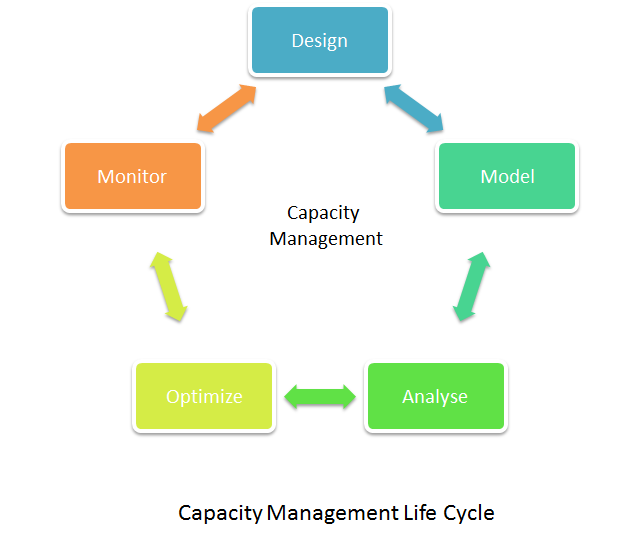

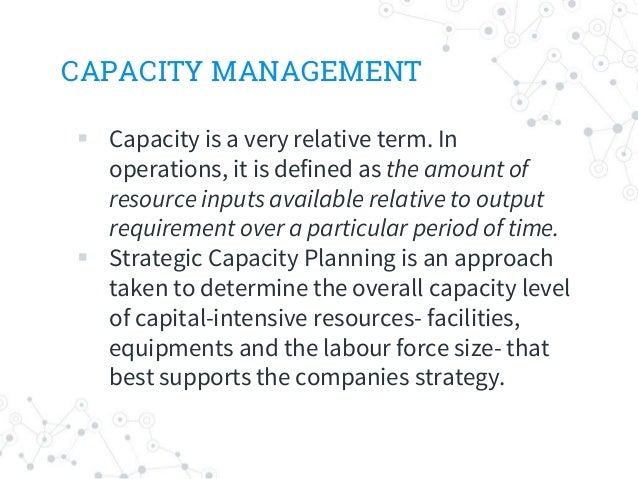

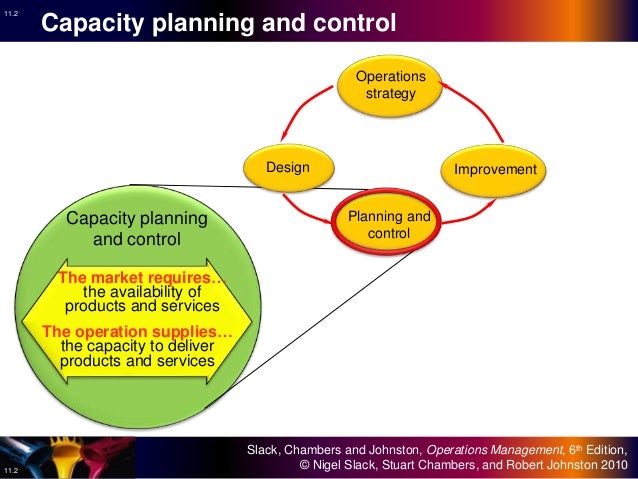

Aug 31, 15 · 11 capacity planning and control_Operations Management A) What is capacity management?Jun 04, · (1) Aggregate planning is an intermediate range planning approach that determines the level of output for a given service or product by managing the capacity using different production strategies Compare and contrast "chase demand" and "level capacity" strategies in aggregate planningLevel Capacity Plan Definition An approach to mediumterm capacity management that attempts to keep output from an operation or its capacity constant, irrespective of demand Operations Management by Nigel Slack, Alistair BrandonJones, Robert Johnston Level Capacity Plan

AGGREGATE PLANNING 1 What is aggregate planning?Often used for maketostock products like appliances ?A) use of backorders B) use of overtime C) use of subcontractors D) use of temporary workers 12 Which of these is not a disadvantage of a level approach as compared to a chase approach?

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Capacity Planning And Control Ppt Video Online Download

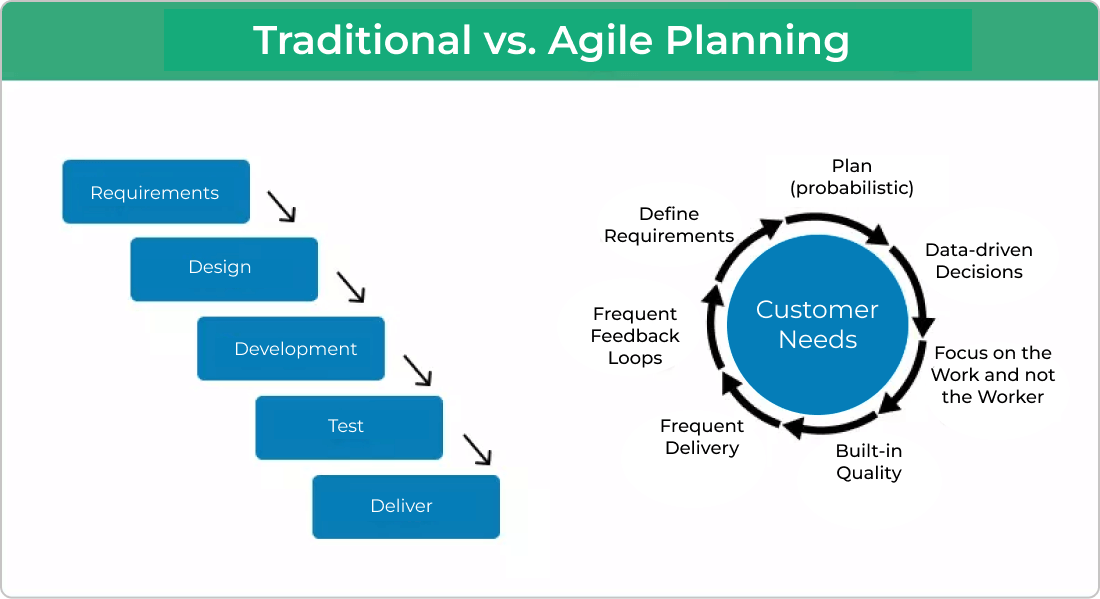

Jan 14, · The primary difference among the three strategies is the lever, that is, the parameter that is manipulated to achieve equality of supply and demand over the aggregate planning period The first chase strategy uses capacity, in the form of machine or personnel capacity, as the leverSimply put, if capacity is the means to plan and achieve, then capacity development describes the ways to those means An essential ingredient in the UNDP capacity development approach is transformation For an activity to meet the standard of capacity development as practiced and promoted by UNDP, it must bring about transformation that isPlanning a chase approach C) master scheduling D) shortrange planning 11 Which of these is not considered to be a capacity option?

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

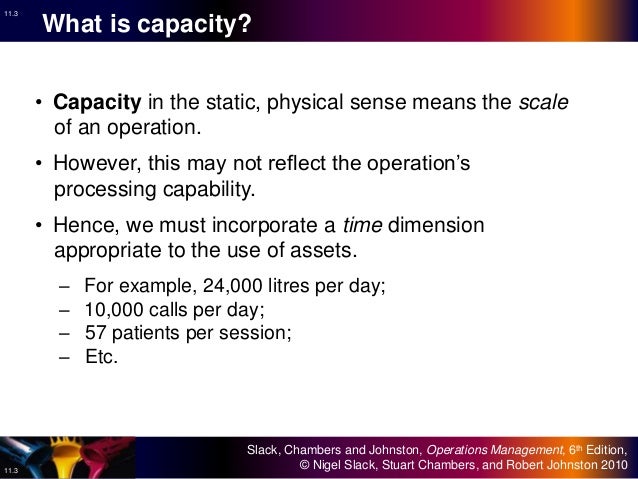

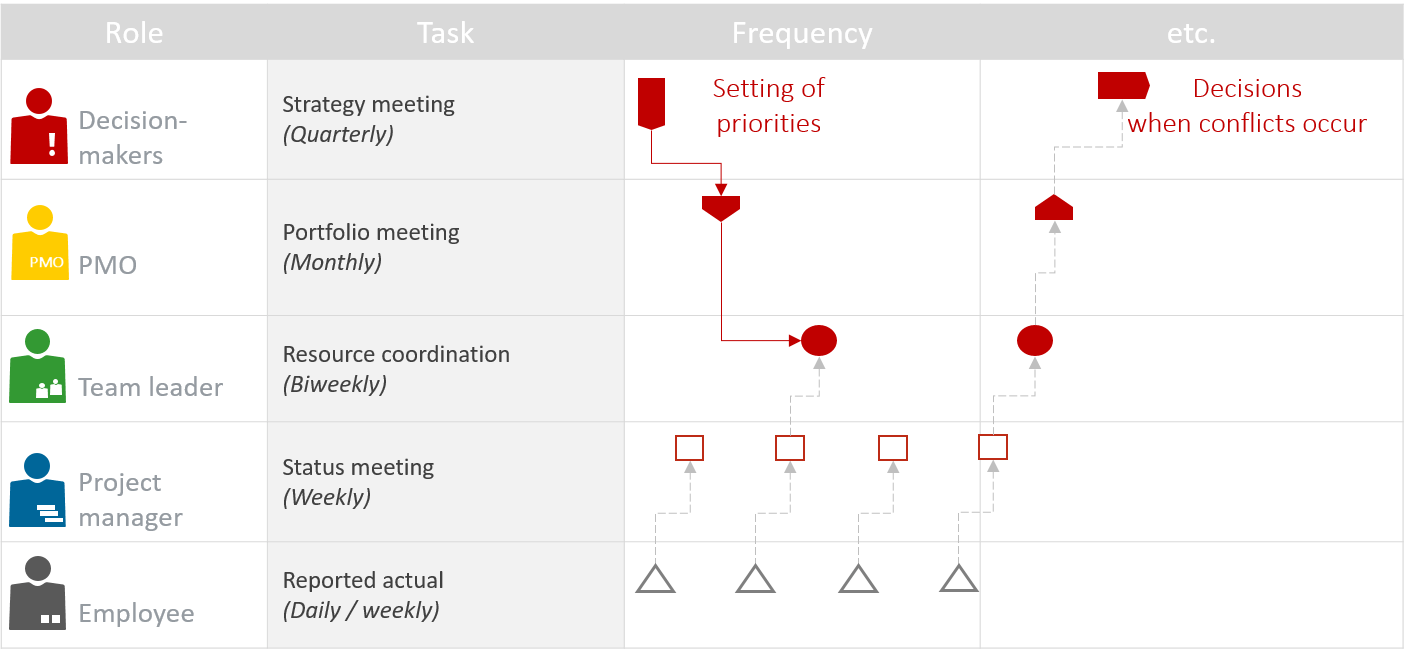

Nov 26, 19 · Capacity Planning Checklist Here's a short checklist for highlevel capacity planning Establish CrossFunctional Team To collaborate and communicate about resources, as you're looking across different projects or programs, you want a crossfunctional team with different levels and different functionsSep 29, 19 · Capacity planning is described as a tool to minimize the discrepancy between the capacity of a business entity and customer demands Demand for capacity is variable as it is based on changes in production output of an existing product or in the production of a new productOct 01, 18 · Capacity planning is an integral part of the overall production planning for an enterprise Capacity planning and control is the process of establishing, measuring, monitoring and adjusting the levels of capacity in order to execute all manufacturing plans and schedules in the best possible manner

Ppt Strategic Capacity Planning Defined Powerpoint Presentation Free Download Id

Top 12 Resource Management Best Practices Planview

This revision video provides an overview of the concept of capacity, capacity utilisation and some of the issues facing businesses operating at low or high uSep 01, 1996 · The purpose of this paper is to describe the operational features of the four capacity planning techniques, the underlying data base requirements, and some key managerial issues in choosing amongEach method is based on reacting to or planning for market fluctuations and changing levels of demand These capacity planning strategies are match, lag, lead, and adjustment Match Matching involves monitoring the market for demand increases and decreases on a regular basis

Itil Capacity Management Bmc Software Blogs

Capacity Planning Everything You Need To Know Clicktime

May 17, 21 · Capacity planning is the practice of planning/determining production capacity and workforce needs to make sure your supply chain is equipped to meet demand Capacity planning lets businesses know how and when to scale, identify bottlenecks, create better design capacity, and mitigate risk, within a planned period of timeMay , 09 · Over the past decade, many organizations have adopted the agile approach to managing projects But despite its widespread use, many organizations and project professionals struggle in adapting the approach to accommodate their requirements This paper examines how project managers can use agile's main principles to plan a project's scope, time, and costTypes of aggregate plans Level Aggregate Plans – planning approach > same quantity each time period Inventory & backorders used to absorb demand fluctuations ?

Capacity Planning And Management Case Study Example Topics And Well Written Essays 1250 Words

Aggregate Planning Definition Importance Strategies Management And Advantages

Maintains a constant workforce ?General approach for the development of an aviation training At a detailed level, the roadmap will provide CAAs and aviation service providers plans of actions to ensure they meet capacity needs in terms of occupations, to develop or maintain the number capacity‐building plans established by ICAO Member States3) Match or tracking capacity strategy 1) Lead capacity strategy a proactive approach that adds or subtracts capacity in anticipation of future market conditions and demand 2) Lag capacity strategy a reactive approach that adjusts its capacity in response to demand 3) Match or tracking capacity strategy

Capacity Planning Types Lead Lag Average Strategies Video Lesson Transcript Study Com

1

• What service level should be offered to broadband customers?Process of capacity planning because the provide information on future demand Thus, the importance of forecasting to capacity planning cannot be overstated The primary goal of capacity planning is to match supply to demand Having a forecast of demand is essential for determining how much capacity will be needed to meet present and future demandThis 4year project focused on building operational level public health emergency response capacity, which had not previously been part of any national program Use of the allhazard approach rather than a scenariobased contingency planning led to the development of a standardized curriculum for training both inservice and preservice personnel

Capacity Management It Process Wiki

Aggregate Capacity Planning Pdf Free Download

Jan , 16 · Capacity planning is a strategic process whereby a company determines what level of capacity it will need to satisfy the level of A middle approach is an average strategy where capacityLevel Capacity Strategy 1 The utilization of operational resources throughout the year 2 Efficient level of production can be maintained 3 Decreases the marginal costCapacity Planning and Management are explained in this videoThe text was created by an experienced Lean Thinker that gives his point of view on the "Capacit

Pdf A Multi Level Modeling Approach For Simulation Based Capacity Planning And Scheduling Of Aircraft Maintenance Projects Semantic Scholar

Capacity After Deciding What Products Services Should Be Offered And How They Should Be Made Management Must Plan The Capacity Of Its Processes Capacity Ppt Download

Sets capacity to accommodate average demand ?When planning capacity there are always two sides to consider firstly there is the demand – the amount of the product or service that might be wanted;And secondly there is the provision of the good or service

Chapter 5 Strategic Capacity Planning For Products And Services Pdf Free Download

Topic Capacity And Facilities Subject Operation Management Guided

Jul 01, 21 · An approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of qualityJun 28, 13 · 32 Example RoughCut Capacity Planning Texprint Company makes a line of computer printers on a producetostock basis for other computer manufacturers Each printer requires an average of 24 laborhours The plant uses a backlog of orders to allow a levelcapacity aggregate plan This plan provides a weekly capacity of 5,000 labor hoursThe purpose of aggregate planning is planning ahead because it takes time to implement plans

Level Capacity Plan Approach Ppt Powerpoint Presentation Summary Cpb Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Level Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers (working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventoryTo develop a sustainable regional approach to building operational level capacity for disaster planning This project was implemented through a higher education leadership initiative Project activities were spearheaded by a network of Deans and Directors of public health schools within local universities in the Eastern Africa regionUniversity partnerships are an effective method to build districtlevel disaster planning capacity Use of a regional network created a standardized approach across six countries University partnerships are an effective method to build districtlevel disaster planning capacity

Capacity Planning Everything You Need To Know Clicktime

Cmg Org Wp Content Plugins S2member Files Proceedings 17 5 Ja Baker Pdf

Sep 17, 15 · LTE Capacity Planning and PRB Dimensioning Ensuring Quality of Service in an Increasingly Complex Network RAN networks look very different today than they did in the past – meaning network planners have their work cut out for them Complexity, the amount of traffic, and the number of network elements are all increasing – all beingCapacity planning is the process of determining the production capacity needed by an organization to meet changing demands for its products In the context of capacity planning, design capacity is the maximum amount of work that an organization is capable of completing in a given period Effective capacity is the maximum amount of work that an organization is capable of completingThe aggregate plan is derived from the company's overall business plan True Aggregate production strategies are part of your _______________ planning Intermediate range A common approach today is to use outsourcing to satisfy shortterm increases in demand True The level strategy and the chase strategy are examples of a (an

Capacity Planning And Control Ppt Download

Level Capacity Plan Approach Ppt Powerpoint Presentation Summary Cpb Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

The next level of operational, programmatic, financial, or organizational maturity, so Sector New England (TSNE), suggests that a network approach to capacity building is a more effective way to create social change on a large scale Through data gathered over the course of an eightyear network planning Whatever the reason, examplesB) Measuring demand and capacity C) The alternative capacity plans D) Choosing a capacity planning and control approach E) Capacity planning as a queuing problem Read more Brent Weeks SelfEmployedMay 05, · Capacity Planning Dashboard On the left side, you will have the slicers (filters) that you can use to drill down to specific Project(s), Skill group(s) and Resource(s) Dashboard Slicers At the top, you will see the overall summary of metrics Capacity Planning Dashboard –

Match Supply And Demand In Service Industries

11 Capacity Planning And Control Operations Management

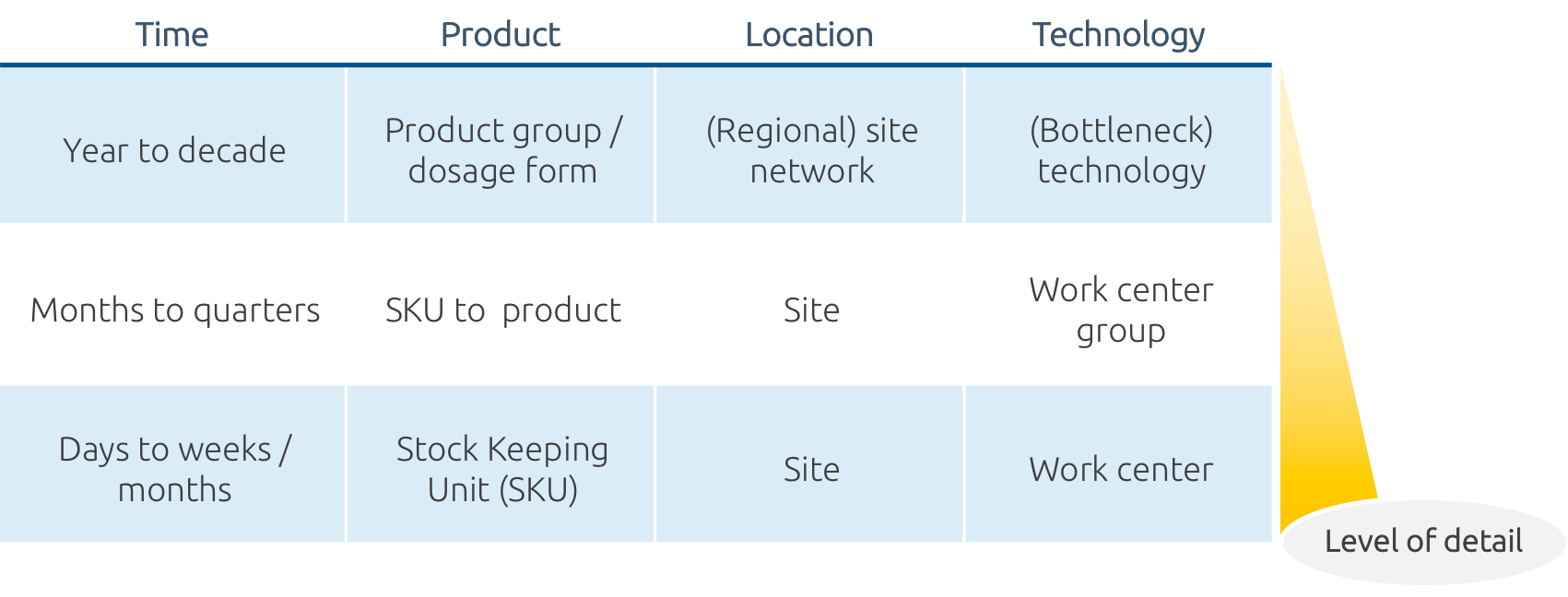

In production planning, it is the intermediaterange capacity planning that typically covers a time horizon of 2 to 12 months What is the purpose of aggregate planning?

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

1

Which Of The Following Is Not A Factor In Capacity Chegg Com

Operations Management Chase For Competitive Advantage Aquilano Ninth

Production Planning Wikipedia

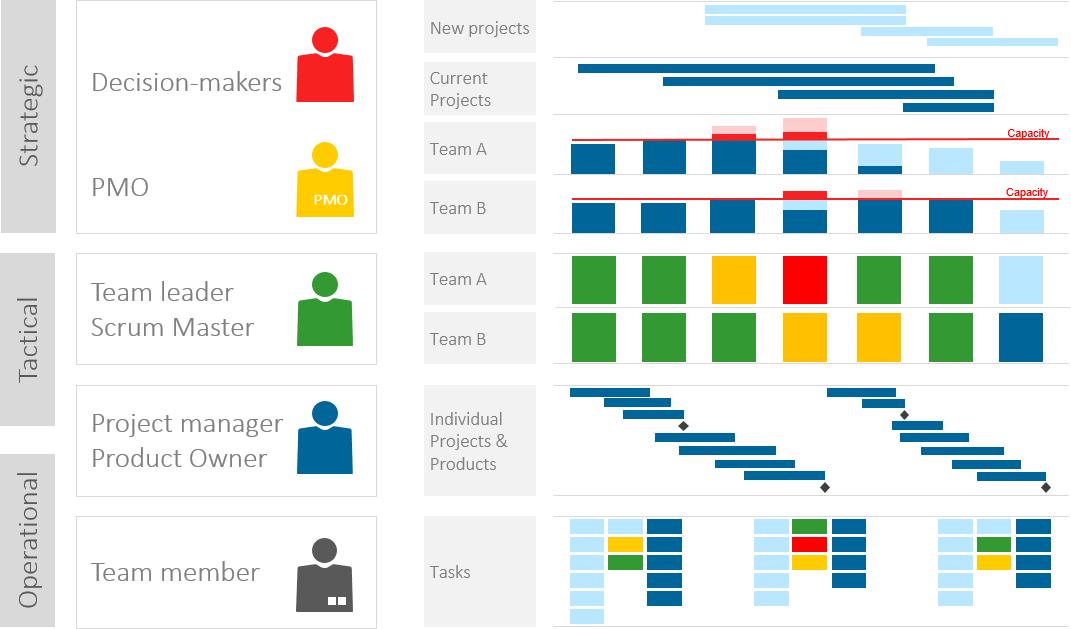

Choosing The Right Planning Approach For The Case Company Download Scientific Diagram

Capacity Planning Everything You Need To Know Clicktime

The Complete Beginners Guide To Agile Project Planning

Capacity Planning

Book Production And Operations Management

Demand Capacity Planning Jsc

Evaluating Capacity Development Better Evaluation

Aggregate Capacity Planning Pdf Free Download

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Nipn Capacity Development Plan Nipn

Mcq S Week 7 Capacity Management Chapter Week Capacity Management Which Of The Studocu

The 3 Steps Of Capacity Planning And How They Apply To Your Process

Production Planning An Overview Sciencedirect Topics

Pdf A Multi Level Modeling Approach For Simulation Based Capacity Planning And Scheduling Of Aircraft Maintenance Projects Semantic Scholar

Chapter 3 Strategic Capacity Management Ppt Download

Sales And Operations Planning Relex Solutions

Everything About Capacity Planning Strategies Its Benefits

Solved Which Of The Following Is Considered To Be Advanta Chegg Com

Everything About Capacity Planning Strategies Its Benefits

Project Scheduling Approach To Production Planning Citeseerx

Jira Work Management Atlassian S New Solution For Business And Operations Teams Oxalis Io

Iteration Planning Scaled Agile Framework

Capacity Planning Cp 1 Ppt Powerpoint

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Ch11 Strg Capacity Mgt Ppt Powerpoint

The Four Levels Of Capacity Development Download Scientific Diagram

5 1 Capacity Planning Operations Management William J

A Multi Level Modeling Approach For Simulation Based Capacity Planning And Scheduling Of Aircraft Maintenance Projects Semantic Scholar

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

Aggregate Plans For Companies With Tangible Products Operations Management An Integrated Approach 5th Edition Book

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Strategy And Governance Eitbok

Production Planning An Overview Sciencedirect Topics

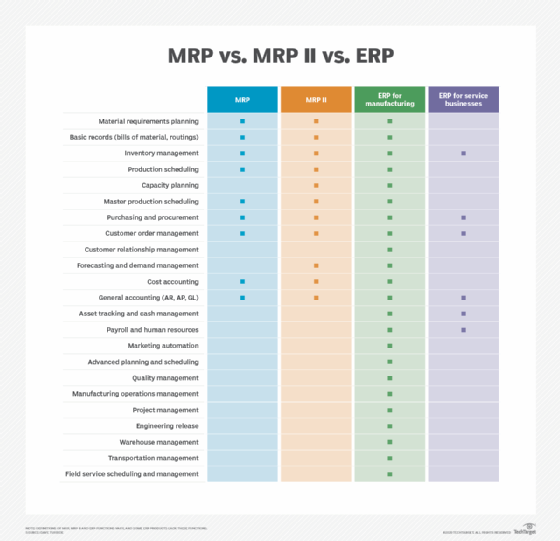

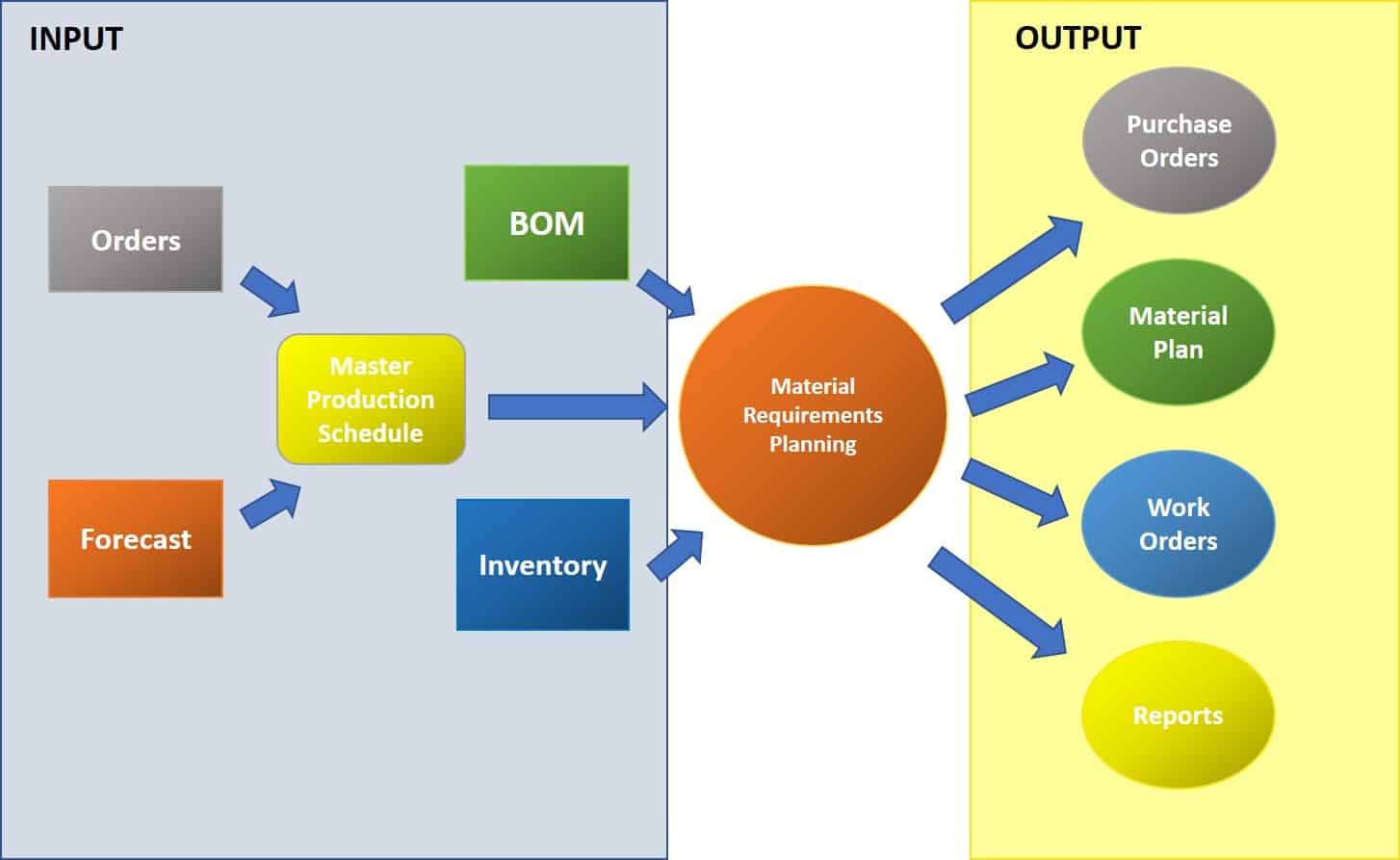

What Is Material Requirements Planning Mrp

Chapter 12 Aggregate Planning Doc Inventory Mathematical Optimization

Aggregate Planning Lecture Notes 10 14 Studocu

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

What Is Capacity Planning Examples Types Optimoroute

11 Capacity Planning And Control Operations Management

What Is Capacity Planning Examples Types Optimoroute

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

1

Production Planning Wikipedia

Evaluating Capacity Development Better Evaluation

Success Factors For Ddmrp In A Constrained Manufacturing Environment I Camelot Blog

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

What Is Capacity Management Definition And Faqs Omnisci

Everything You Need To Know About Material Requirements Planning Mrp Smartsheet

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Your Guide To The Key Steps Of Capacity Planning And Management Galileo Performance Explorer

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity Management

1

Capacity Planning And Control Ppt Video Online Download

What Is Capacity Planning Examples Types Optimoroute

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity Management In Industrial Engineering Economies Of Scale Output Economics

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Production Planning Control Chapter 2 Aggregate Planning Master Production Scheduling Chapter2 1 Pdf Free Download

11 Capacity Planning And Control Operations Management

Optimizing Productivity Analysis For Better Factory Performance Applied Materials

Pdf An Approach To Capacity Planning Of Distribution Warehouses For X Firm Semantic Scholar

Elements Of Who Capacity Building Plan 36 Download Table

Pdf An Optimisation Approach For Capacity Planning Modelling Insights And Empirical Findings From A Tactical Perspective Semantic Scholar

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

What Is Capacity Planning Examples Types Optimoroute

Importance Of Capacity Planning Docx Employment Design

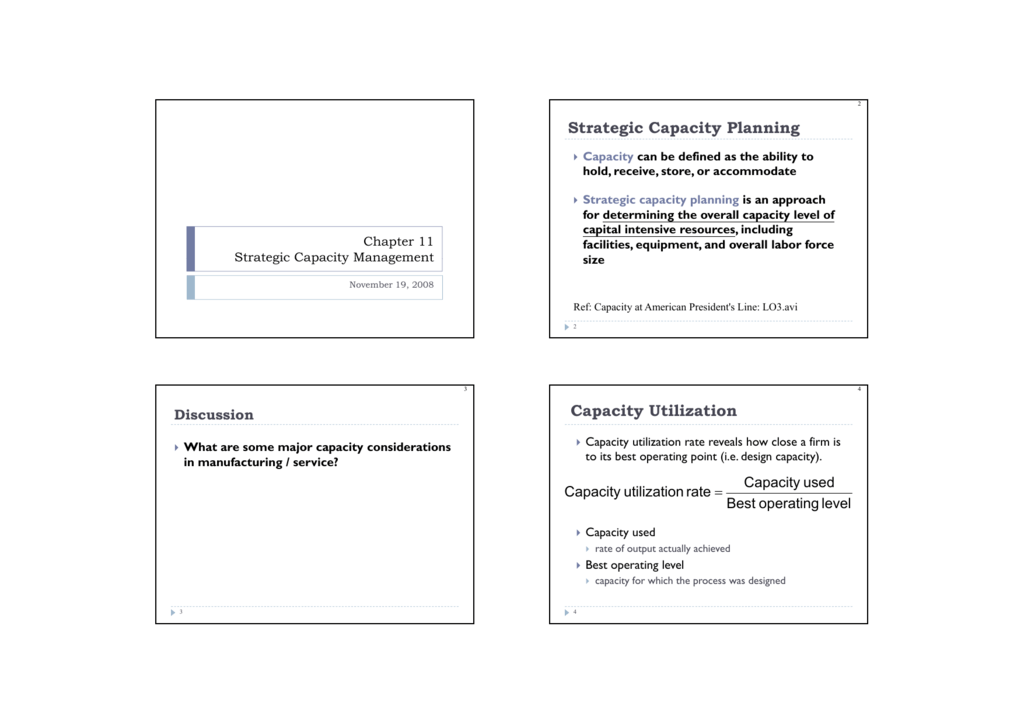

Strategic Capacity Planning Capacity Utilization

Topic Capacity And Facilities Subject Operation Management Guided

Who Human Capacity Building Plan For Scaling Up Hiv Aids Treatment

Capacity Planning Everything You Need To Know Clicktime

4 Steps To Strategic Human Resource Planning Lucidchart

0 件のコメント:

コメントを投稿